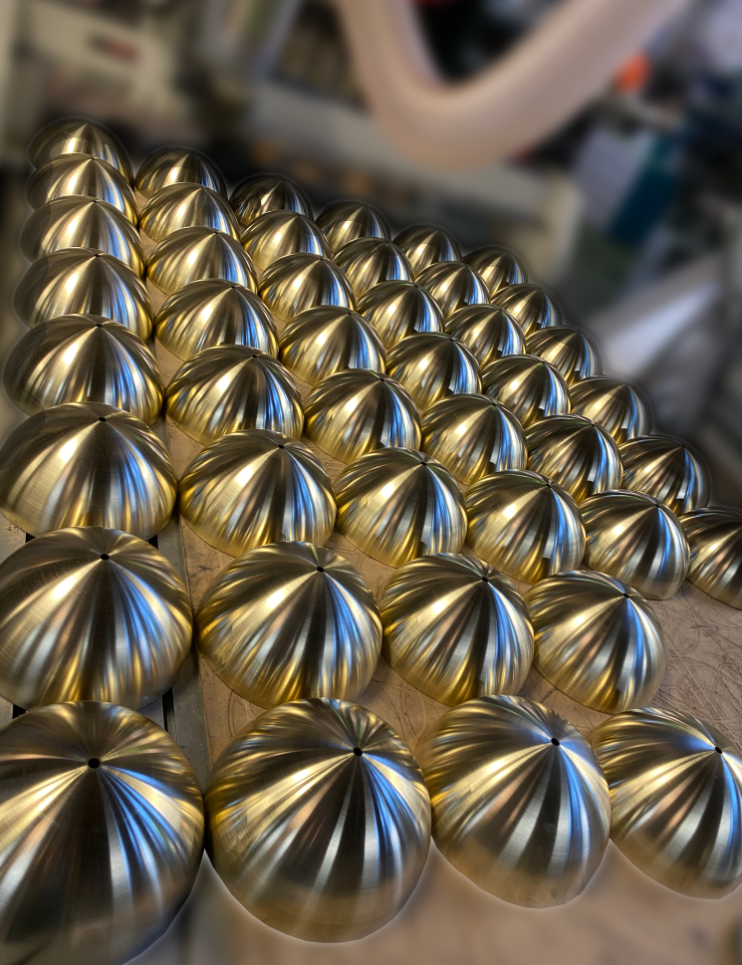

Turbon spins Brass just like it’s Butter – 300mm hemispheres made from solid 1.2mm thick brass and destined to become a part of some very special light fittings.

We make things sweeter

Turbon is now on it’s 3rd run of processing calandrea evaporation tubes used in the sugar mills. This now totals production of over 42000 units that we have processed in our Brisbane factory and warehouse. Now thats a lot of tubes to handle, count and even write up delivery dockets for, and with the nature of the work being very repetative, we have let our small and dedictaed processing team “turn up the radio”.

A basic Introduction to Metal Spinning

The origin of metal spinning dates back to the Egyptian era when humans used their power to spin soft metals into desired objects and antiquities. Today metal spinning is not very different from the ancient art except that modern technology has made the process quicker.

In metal spinning, a rotating metal sheet is misshapen and spun into metal parts and objects. Metal spinning can be performed on a range of metals like aluminum, copper, stainless steel, mild steel, brass, etc.

The end products are usually in the shapes of cylinders and cones i.e. shapes hollow from inside. The products are then finished, which gives them the characteristic perfect shine.

Types of Metal Spinning

Metal spinning lathes are of three types described as follows:

Manual Spinning, as obvious from the name, needs human skill and involvement. It can work with sheets or blanks ranging from 6.35 mm to 1.8m in diameter.

Power Assisted Spinning lathes are used to spin stronger metals e.g. stainless steel. The additional power, along with human input, is provided by hydraulic cylinders.

Automatic Spinning lathes are used for the production of high volume with precision. It uses Computer Numerical Control (CNC) or Programmable Numerical Control (PNC) for automation.

Decline of Metal Spinning

● The art of metal spinning is not appreciated as it used to be in recent history. In ancient times, it used to be a sacred learning trade and it produced remarkable craftsmen and antiques.

● But nowadays, it is not taken as the marvel it is. No one wants to learn the trade. They all want it quick and automated.

● There is nothing wrong with automated technology, but it still requires the craftsmanship of metal spinning. No one is interested in experiencing metal spinning hands on.

● Modern spinning technology is all about producing large volume runs instead of relishing the art and creating imaginative pieces. Hence industry is losing its origin and meaning.

Metal Spinning- An Undermined Career Path

● It is a well known fact that to master metal spinning, one needs a relatively long period of learning and apprenticeship. The sacred master-protege relationship gives birth to the expert level skill of metal spinning.

● Even if one has all the mechanical setup, it still requires skilled hand to eye coordination, which can only be learned with passion and consistency.

● The most unfortunate thing for this industry is that it is still not recognized as a proper career path. There is no formal education or specialization being offered in metal spinning.

● It is usually passed onto the son from his father. Hardly any newcomers enter the field as it is not considered a full time and rewarding career.

Modern Spinning Technology

● Modern spinning technology is a step forward in this field. It uses automated lathes and machines which enable the spinners to accelerate the process partially.

● CNC and PNC are both automated metal spinning processes. Once programmed, these can automatically produce the end product as desired.

● But to program it, especially in PNC, the first round has to be manual spinning to program the machine.

● Hence even modern automation technology requires an expert metal spinner to initiate the whole process.

Metal spinning cannot flourish or even survive without skilled spinners who have been learning it for over a decade now. They are integral to the growth and preservation of this art. To create master metal spinners, it must be introduced as a fulfilling career and other fields of formal education.

Specialised Copper Cookware

Turbon Manufactures Specialised Copper Cookware for Commercial Kitchens –

Nothing beats copper cookware for beating egg whites or melting sugars. Copper cookware is like the Rolls-Royce of all pots and pans! Not only is it aesthetically appealing, it is the ultimate conductor of heat! A copper pan will heat up quickly and evenly along the bottom, walls and edges with no hotspots or uneven heating. This means the top of the pan will be as hot as the bottom so your food heats and cooks evenly. To give you an idea, copper has a thermal conductivity (i.e. ability to conduct heat) that is TWICE that of aluminium (which is considered a good conductor of heat anyway) and almost 20 TIMES that of stainless steel!

Our Diversity just Stepped it Up a Notch

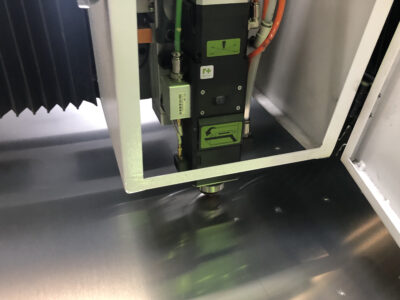

Turbon now boasts having an in-house Fibre Laser Cutter using the nLight Laser Source (USA) so cutting Copper Brass and Aluminium as well as your Stainless and Steel based metals has become a breeze. Along with our other CNC technologies, Metal Spinning and Routing and as well as having a fully optioned machine shop we can maintain most of our processes in house. You are Limited only by your Imagination.

Turbon’s diversified interest.

Blue Sun Poles were chosen to supply the road lighting poles for a major highway project in P.N.G. Comprising over 250 poles fitted with double outreach arms and foundation systems these poles were engineered and manufactured for a tough environment and supplied within a tight delivery time frame of 8 weeks.

We had these poles manufactured by our supplier in Wuxi which is about 2 hours outside of Shanghai in China. Based on a tight relationship formed with this manufacturer over many years the issues associated with quality control had become a thing of the past.